Wholesale Price Small Wet Mix Concrete Batching Plant - D series cement silo top type SjHZS120D – Janeoo

Wholesale Price Small Wet Mix Concrete Batching Plant - D series cement silo top type SjHZS120D – Janeoo Detail:

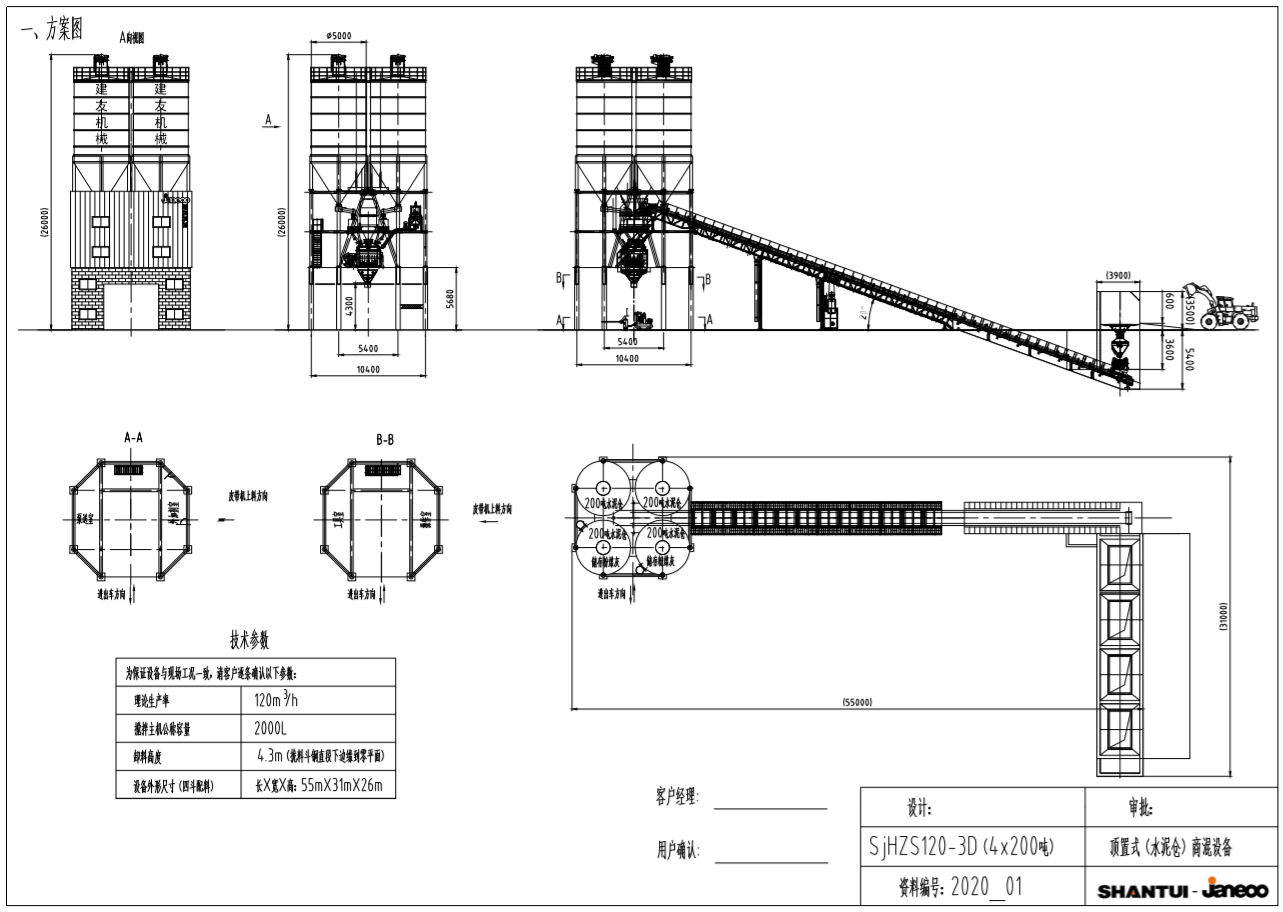

Specification

|

No. |

Description |

Item |

Origin |

QTY |

Remark |

|

|

1 |

Aggregates batching machine (4 bunkers) |

Storage hopper |

Janeoo |

4 |

Including 2 sand hopper and 2 vibrators | |

| Weighing hopper(2000kg±2%) |

Janeoo |

4 |

||||

| Cylinder |

SMC |

3×4 |

||||

| Sensor |

Toledo |

3×4 |

||||

| Beltmachine(B:1000mm,P:5.5KW) |

Janeoo |

1 |

||||

|

2 |

Inclined belt machine |

Main support |

Janeoo |

1 |

|

|

| Driving device(P:37kW) |

Janeoo |

1 |

||||

| Conveying belt(B:1000mm) |

Janeoo |

1 |

||||

| Washing device |

Janeoo |

1 |

||||

|

3 |

Main building |

Concrete structure |

By customer |

1 |

|

|

| Main frame(2 layers) |

Janeoo |

1 |

||||

| Discharging hopper |

Janeoo |

1 |

||||

| Bag filter |

Janeoo |

1 |

||||

| Decoration(excluding silo)(75mm) |

Janeoo |

1 |

||||

|

4 |

Mixer |

Volume 2.0 m3(Power:2X37kW) |

Janeoo |

1 |

|

|

| Hydraulic structure |

Janeoo |

1 |

||||

| Lubrication system |

Janeoo |

1 |

||||

|

5 |

Mid-storage hopper |

Main hopper |

Janeoo |

1 |

|

|

| Vibrator |

Oli |

1 |

||||

| Cylinder |

SMC |

2 |

||||

|

6 |

Cement weighing system |

Weighing hopper(1000kg±1%) |

Janeoo |

1 |

|

|

| Sensor | Toledo |

3 |

||||

| Valve(DN300) |

WAM |

1 |

||||

| Vibrator |

Oli |

1 |

||||

|

7 |

Powder weighing system

|

Weighing hopper(400kg±1%) |

Janeoo |

1 |

|

|

| Sensor |

Toledo |

3 |

||||

| Valve(DN300) |

WAM |

1 |

||||

| Vibrator |

Oli |

1 |

||||

|

8 |

Water weighing system |

Weighing hopper(500kg±1%) |

Janeoo |

1 |

|

|

| Sensor |

Toledo |

1 |

||||

| Valve (DN150) |

Janeoo |

1 |

||||

| Water pump |

Janeoo |

1 |

||||

| Valve(DN80) |

Janeoo |

1 |

||||

| Pipes |

Janeoo |

1 |

||||

|

9 |

Additive weighing system |

Weighing hopper(50kg±1%) |

Janeoo |

1 |

PE |

|

| sensor |

Toledo |

1 |

||||

| valve (DN100) |

Janeoo |

1 |

||||

| Storage tank 10m3 |

Janeoo |

3 |

||||

| Additive pump |

Janeoo |

3 |

||||

| Pipes |

Janeoo |

3 |

||||

|

10 |

Pneumatic system |

Air compressor(displacement 1.6 m3/min) |

Atlas |

1 |

|

|

| Storage tank 1.0m3+0.3m3 |

Janeoo |

1套 |

||||

| Filter、valve |

SMC |

1 |

||||

|

11 |

Control room |

Concrete structure |

By customer |

1 |

|

|

| Air conditioner |

Haier |

1 |

||||

|

12 |

Electrical system |

Software |

Janeoo |

1 |

||

| Industrial computer |

siemens |

1 |

||||

| UPS power |

Janeoo |

1 |

||||

| Printer |

OKI |

1 |

||||

| Operating carbin |

Janeoo |

1 |

||||

| Main electric component |

schneider |

1 |

||||

| monitoring system 4 cameras and 1 monitor |

Janeoo |

1 |

||||

| List of supporting equipment for selection (the selection part shall be subject to the sales contract) | ||||||

|

No. |

Description |

Item |

Origin |

Qty |

Remark |

|

|

13 |

Cement silo |

300t |

Janeoo |

4 |

Cement density 1.35t/m3 |

|

|

14 |

Accessories |

24㎡ filter(pulse type) |

Janeoo |

4 |

|

|

| Top save valve |

Janeoo |

4 |

||||

| Level meter |

Janeoo |

2X4 |

||||

| Arch breaker |

Janeoo |

4 |

||||

| Valve |

Janeoo |

4 |

||||

|

15 |

Wind chute |

Chute |

Janeoo |

4 |

|

|

| Valve |

WAM |

4 |

||||

Product detail pictures:

Related Product Guide:

We keep on with the basic principle of "quality to start with, support very first, continuous improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for Wholesale Price Small Wet Mix Concrete Batching Plant - D series cement silo top type SjHZS120D – Janeoo , The product will supply to all over the world, such as: Sierra Leone, Wellington, Southampton, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!