High Quality China Supplier Dry Mix Concrete Batch Plant - SjGZD060-3G Station Type Dry Motar batching plant – Janeoo

High Quality China Supplier Dry Mix Concrete Batch Plant - SjGZD060-3G Station Type Dry Motar batching plant – Janeoo Detail:

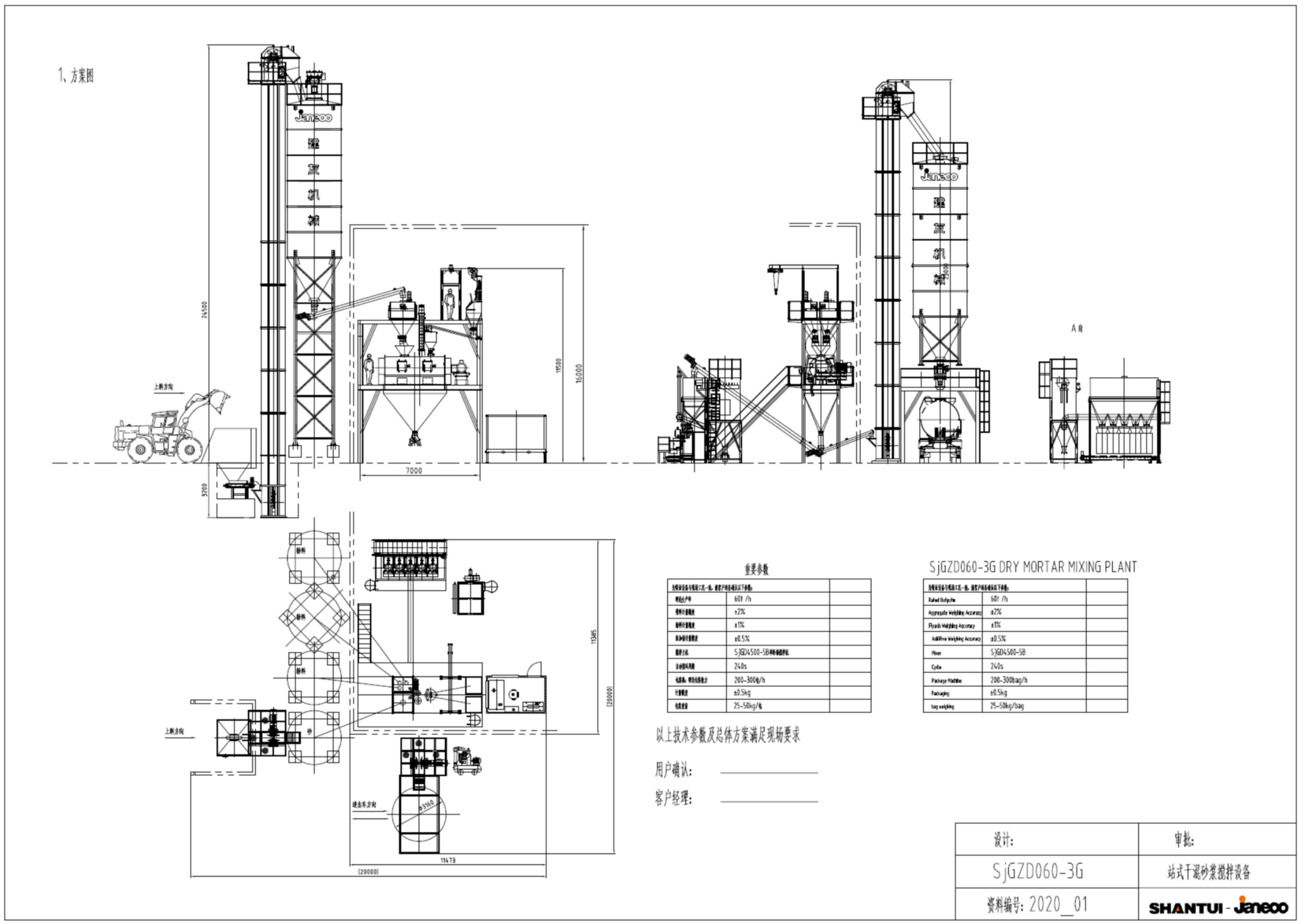

Main specifications

1.main specifications

Theoretical productivity 60t/h

Mixer SjGD4500-5B

aggregates measuring accuracy 2

Cement measuring accuracy 1%

additive measuring accuracy 0.5%

Sand silo volume 72m3

Cement silo volume 72m3

Additive silo volume 0.5m3

Packing capacity 200-300bags/h/set

Total power 140kW(excluding silo and screw conveyors)

1.Sand silo

| Volume | 72m3 |

| Diameter | 3.2m |

2.Cement silo

| Volume | 72m3 |

| Diameter | 3.2m |

3.Additive silo

| Volume | 0.5m3 |

4.Sand batching screw conveyor

| screw diameter | 323mm |

| capacity | 35m3/h |

5.Sand batching screw conveyor

| screw diameter | 273mm |

| capacity | 50m3/h |

6.aggregate measuring hopper

| type | electronic scale |

| Max value | 3000Kg |

| Accuracy | ±2% |

7.Cement measuring hopper

| type | electronic scale |

| Max value | 2500Kg |

| Accuracy | ±1% |

8.Additive measuring hopper

| type | electronic scale |

| Max value | 150Kg |

| Accuracy | ±0.5% |

9.Mixer

| Mixer | SjGD4500-5B |

| Motor power | 90Kw |

| Blade power | 4×5.5Kw |

10.Packing machine

| Packing capacity | 200-300 bags/h/set |

| Each bag weight | 25~50Kg |

| Accuracy | ±0.5 Kg |

11.pneumatic system

| air compressor power | 30kW |

| pressure | 0.75MPa |

12.dust removal system

| Filter | 60m2 |

| Power | 7.5kW |

20.electrical system

The system is powered by ac 380V and 50Hz three-phase four (five) wire system.

21.Computer control

Manual and automatic

22.cycle time

| Auto | 240s |

Description

SjGZD060-3G station type dry mortar mixing equipment is a kind of equipment designed and developed by our company according to the similar products abroad and combined with the actual situation in China.It is suitable for mixing ordinary dry mortar and special dry mortar.

The main equipment adopts station structure, including 1 sand bin (72m3/ piece), 3 powder bin (72m3/ piece), and 2 additive bin (0.5m3/ piece).The sand is lifted by a bucket machine, the powder is transported to the powder silo by a bulk tank truck, and the two additives are lifted to the additive silo layer by an electric lifting device and put into the additive silo manually.Sand, powder, additives using screw conveyor batching, measuring bucket using electronic scale measurement, measurement accuracy is high, small error.The control system adopts manual and automatic control.The system has perfect self-locking and inter-locking functions to ensure accurate and reliable operation of the system, and has common fault detection and alarm functions.

Configuration

| 一、 Main building | ||||

| No. | Description | Item |

Qty |

Remark |

|

1 |

weighing scale |

1 |

|

|

| weighing scale Max.3000kg |

1 |

|||

| pressure load cell |

3 |

|||

| load cell connecting parts |

3 |

|||

| (DN300) pneumatic butterfly valve (DN300) |

2 |

|||

| MVE60/3 vibrator MVE60/3 |

1 |

|||

| cement weighing scale Max.2500kg |

1 |

|||

| pressure load cell |

3 |

|||

| load cell connecting parts |

3 |

|||

| pneumatic butterfly valve (DN250) |

2 |

|||

| vibrator MVE60/3 |

1 |

|||

|

2 |

additive storage silo |

1 |

|

|

| additive bin (volumn: 0.5m3) |

2 |

|||

| Resistance twist-action indicator |

2 |

|||

| manual butterfly valve(DN250) |

2 |

|||

| transverter |

1 |

|||

| vibrator MVE60/3 |

2 |

|||

|

3 |

additive weighing scale |

1 |

|

|

| Max. weighing scale 150kg |

1 |

|||

| load cell |

3 |

|||

| pneumatic butterfly valve (DN200) |

1 |

|||

| pneumatic butterfly valve Ø250 |

1 |

|||

| MVE60/3 vibrator MVE60/3 |

1 |

|||

|

4 |

additive hoisting devices |

1 |

|

|

| frame |

1 |

|||

| 1000Kg Electric Hoist 1000KG |

1 |

|||

|

5 |

手工投料装置Manual feeding device |

1 |

|

|

| manual feeding bin |

1 |

|||

| pneumatic butterfly valve (DN200) |

1 |

|||

|

6 |

mixing system |

|

|

|

| supporting base(Q235 Steel structure) |

1 |

|||

| Tank body(16Mn Steel structure) |

1 |

|||

| access gate(16Mn Steel structure) |

2 |

|||

| ischarging gate(16Mn Steel structure) |

1 |

|||

| 90KW mixing devices |

1 |

|||

| mixing shaft and shaft end |

1 |

|||

| discharging devices |

1 |

|||

| Sampling device |

1 |

|||

| sampling tube body(structure components) |

1 |

|||

| sampling cylinder |

1 |

|||

| manual directional valve |

1 |

|||

| auxiliary mixing devices |

4 |

|||

| Fly cutter device |

4 |

|||

|

7 |

finished hopper |

1 |

|

|

| hopper body(16Mn) |

1 |

|||

| Resistance twist-action indicator |

1 |

|||

| vibrator MVE60/3 |

1 |

|||

| manual butterfly valve(DN250) |

2 |

|||

|

8 |

Products packaging |

1 |

|

|

| finished hoppe |

1 |

|||

| Frame |

1 |

|||

| Resistance twist-action indicator |

2 |

|||

| vibrator MVE60/3 |

1 |

|||

| Valve pocket packaging machine |

1 |

|||

| Belt (L=4500m,B=650mm,2.2kw) |

1 |

|||

|

9 |

dust-removal device |

1 |

|

|

| 7.5KWPulse blow filter |

1 |

|||

| Dust removal piping |

1 |

|||

|

10 |

|

1 |

|

|

| 30KWair compressor 30KW |

1 |

|||

| AFF22C-10D |

1 |

|||

| 1m3 |

1 |

|||

| Gas-way joint |

1 |

|||

|

11 |

control system |

1 |

|

|

| computer |

1 |

|||

| electric components |

1 |

|||

| LCD monitor |

1 |

|||

| 打印机 printer |

1 |

|||

| UPS |

1 |

|||

| control console |

1 |

|||

| cabinet |

1 |

|||

| wire, cable and bridge. |

1 |

|||

|

12 |

control room |

1 |

|

|

| Control room framework |

1 |

|||

| Control room decorate |

1 |

|||

| Lighting and switch |

1 |

|||

| air conditioner 1P |

1 |

|||

|

13 |

steel structure |

1 |

|

|

| platform |

1 |

|||

| ladder |

1 |

|||

| landing legs |

1 |

|||

| screw conveyer | ||||

|

14 |

φ323X5500mm 18.5KW screw conveyer |

1 |

|

|

|

15 |

φ323X3000mm 15KW screw conveyer |

1 |

|

|

|

16 |

φ219X5000mm 7.5KW screw conveyer |

1 |

|

|

|

17 |

φ219X7000mm 7.5KW screw conveyer |

1 |

|

|

|

18 |

φ219X9000mm 9.2KW screw conveyer |

1 |

|

|

|

19 |

Ø114x1500mm, screw conveyer |

2 |

|

|

|

20 |

Ø323-9000 screw conveyer |

1 |

|

|

|

21 |

SNC100 silo |

Diameter:3.2m,V:72m3 |

3 |

|

| Arch break device |

3 |

|

||

| Manual valve(DN300) |

3 |

|

||

| Rotary level meter |

6 |

|

||

| Silo top safe valve |

3 |

|

||

| Silo top pulse back flush filter |

3 |

|

||

|

22 |

SNC100 silo |

Diameter:3.2m,V:72m3 |

1 |

|

| Manual valve(DN300) |

1 |

|

||

| Rotary lever meter |

2 |

|

||

| Silo top pulse back flush filter |

1 |

|

||

|

23 |

SNC100 silo |

Diameter:3.2m,V:72m3 |

1 |

|

| Arch break device |

1 |

|

||

| Manual valve(DN300) |

1 |

|

||

| Rotary level meter |

2 |

|

||

| Silo top pulse back flush filter |

1 |

|

||

| support leg, silo body and accessories |

1 |

|

||

|

24 |

Bucket Elevator 60m3/h |

2 |

|

|

| Elevator(24m,11kw) | ||||

| Ladders and Maintenance Platform | ||||

| feeding and discharging chute | ||||

|

25 |

pneumatic valve |

1 |

|

|

| supporting base |

1 |

|||

| cylinder |

1 |

|||

| electromagnetic valve |

1 |

|||

|

26 |

Bulk Mortar loader |

Bulk Mortar loader |

1 |

|

|

27 |

hopper |

1 |

|

|

| buchet |

1 |

|||

| (B=650mm,2.2kW)Belt |

1 |

|||

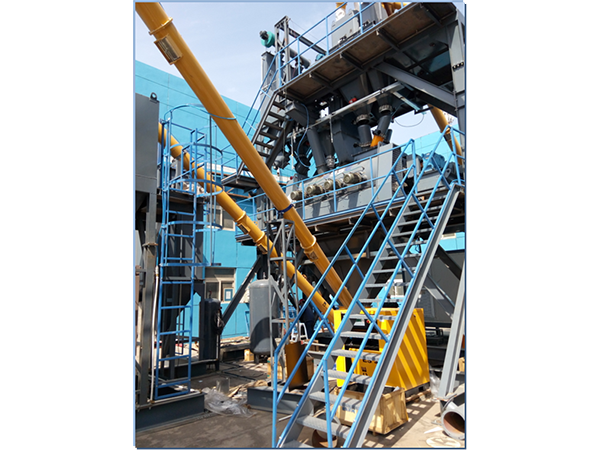

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for High Quality China Supplier Dry Mix Concrete Batch Plant - SjGZD060-3G Station Type Dry Motar batching plant – Janeoo , The product will supply to all over the world, such as: Dominica, Kazakhstan, Luxembourg, Our company's main items are widely used all over the world; 80% of our products and solutions exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!