Good Quality China Supplier Concret Batching Plant Dry Italy - SjGJD060-3GStepped Type Dry Mortar batching plant – Janeoo

Good Quality China Supplier Concret Batching Plant Dry Italy - SjGJD060-3GStepped Type Dry Mortar batching plant – Janeoo Detail:

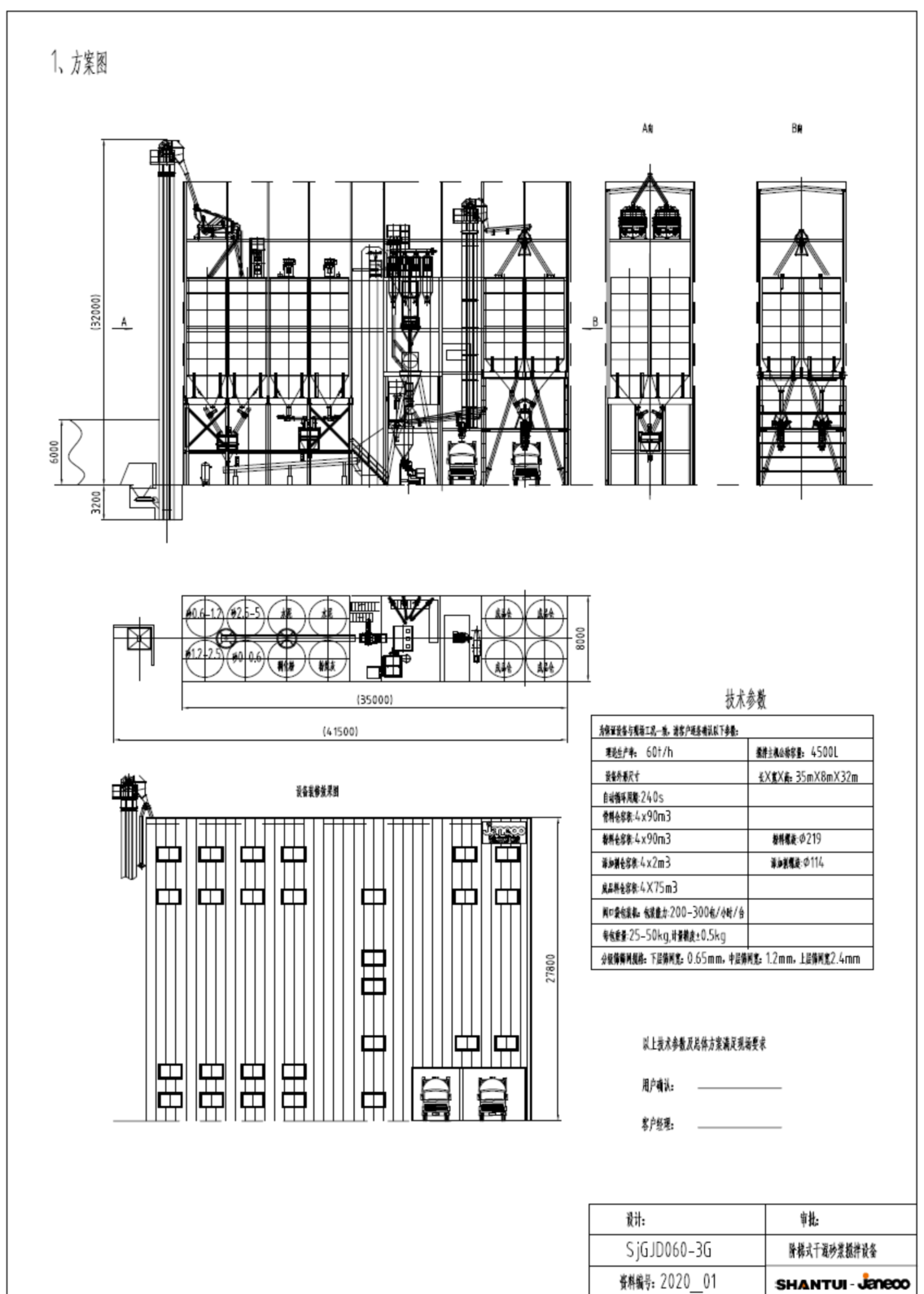

Main specifications

1.main specifications

Theoretical productivity 60t/h

Mixer SjGD4500-5B

aggregates measuring accuracy±2%

Cement measuring accuracy ±1%

additive measuring accuracy ±0.5%

Sand silo volume 4X90m3

Cement silo volume 4X90m3

Additive silo volume 4X2m3

Packing capacity 200-300bags/h/set

Total power 330kW

1.Sand hoisting elevator

| Type | TB60 |

| Hoist speed | 1.1m/s |

| Theoretical capacity | 60m3/h |

| Motor power | 15kW |

2.Graded screen

| Motor power | 2×3.6kW |

| graded layer | 3 layers |

3.Sand silo

| Volume | 90m3 |

| Diameter | 3.4m |

4.Cement silo

| Volume | 90m3 |

| Diameter | 3.4m |

5.Additive silo

| Volume | 2m3 |

| Size | 0.9×0.9m |

6.Production silo

| Volume | 75m3 |

| Diameter | 3.4m |

7.Cement batching screw conveyor

| Diameter | 219mm |

| Capacity | 60t/h |

| Motor power | 5.5kW |

8.Aggregates measuring hopper

| type | electronic scale |

| Max value | 4000kg |

| Accuracy | ±2% |

9.cement measuring hopper

| Mixer | SjGD4500-5B |

| Max value | 1500kg |

| Accuracy | ±1% |

10.additive measuring hopper

| type | electronic scale |

| Max value | 150kg |

| Accuracy | ±0.5% |

11.mixture elevator

| type | TB110 |

| pressure | 1.1m/s |

| capacity | 110m3/h |

| motor power | 22kW |

12.Mixer system

| Mixer | SjGD4500-5B |

| motor power | 90Kw |

| blade power | 4×5.5Kw |

13.packing machine

|

packing capacity |

200~300 bags/h/set |

|

each weight |

25~50Kg |

|

accuracy |

±0.5Kg |

14.production screw conveyor 1 before elevator

| type | GX400 |

| capacity | 42m3/h |

| motor power | 15kW |

15.production screw conveyor 2 in bulk

| type | GX400 |

| capacity | 42m3/h |

| motor power | 11kW |

16.production screw conveyor 3 after elevator

| type | GX400 |

| capacity | 42m3/h |

| motor power | 11kW |

17.Bulk machine

| capacity | 100t/h |

| flexible distance of discharging gate | 1200mm |

| motor power | 0.55kW |

| Filter fan power | 2.2kW |

18.Production hoist elevator

| TB60 | TB60 |

| hoist speed | 1.1m/s |

| capacity | 60m3/h |

| motor power | 15kW |

18.Filter

| Main buliding filter type | HMC48 |

| power | 4Kw |

| packing filter type | HMC48 |

| power | 4Kw |

19.air compressor power:37Kw

20.electrical system

The system is powered by ac 380V and 50Hz three-phase four (five) wire system.

21.computer control

auto and manual

22.cycle time

| auto | 240s |

Description

SjGJD060-3G stepped-type dry mortar batching equipment adopts stepped-type structure, which has the characteristics of large productivity, stability and reliability, and can be used for mixing ordinary dry mortar and special dry mortar.The supporting host machine adopts SJGD4500-5B single horizontal shaft plow-type mixer, which has the characteristics of high mixing efficiency and high mixing uniformity, and the mixing ratio can reach 1:10000.

Configuration

| Standard equipment | ||||

| No. | Description | Item |

Qty |

Remark |

|

1 |

Dry sand hoist device |

1 |

|

|

| (约33m, 15 KW)elevator |

1 |

|||

| platform and ladder |

1 |

|||

| chute of feeding and discharging |

1 |

|||

|

2 |

graded screen |

1 |

|

|

| 3. layers screen nets:lower:0.65mmmid:1.2mm,upper 2.4mm |

2 |

|||

| chute of feeding and discharging |

1 |

|||

|

3 |

砂仓除尘及出料sand silo |

1 |

|

|

| discharging chute |

4 |

|||

| (DN300)valve |

4 |

|||

| pneumatic valve |

4 |

|||

| HMC48 filter |

1 |

|||

|

4 |

cement and sand measuring scale |

1 |

|

|

| 3000kg

sand measuring scale max 3000kg |

1 |

|||

| pressure sensor |

3 |

|||

| (DN250)pneumatic valve |

1 |

|||

| vibrator MVE60/3 |

1 |

|||

| 1500kg |

1 |

|||

| pressure sensor |

3 |

|||

| pneumatic valve(DN250) |

1 |

|||

| vibrator MVE60/3 |

1 |

|||

|

5 |

mixture delivery system |

1 |

|

|

| screw GX500 |

1 |

|||

| accessories |

1 |

|||

|

6 |

mixture hoist elevator |

1 |

|

|

| TB110 elevator (约20m,22kw) |

1 |

|||

| chute of feeding and discharging gate |

1 |

|||

|

7 |

additive feeding and storage tank |

1 |

|

|

| additive silo(V:2m3) |

4 |

|||

| rotary level meter |

4 |

|||

| manual valve(DN300) |

4 |

|||

| pneumatic valve(DN150) |

4 |

|||

| vibrator MVE60/3 |

4 |

|||

| filter system |

1 |

|||

|

8 |

additive measuring scale |

1 |

|

|

| max value 150kg |

1 |

|||

| pressure sensor |

3 |

|||

| pneumatic valve(DN250) |

2 |

|||

| vibrator MVE60/3 |

1 |

|||

|

9 |

additive hoist device |

1 |

|

|

| support |

1 |

|||

| rail |

1 |

|||

| hoist cage |

1 |

|||

| electric hoist 2000Kg |

1 |

|||

|

10 |

manual feeding device |

1 |

|

|

| manual feeding silo |

1 |

|||

| pneumatic valve(DN200) |

1 |

|||

|

11 |

mid-storage hopper |

1 |

|

|

| hopper body |

1 |

|||

| pressure sensor |

1 |

|||

| pneumatic valve(DN300) |

2 |

|||

| vibrator MVE60/3 |

1 |

|||

|

12 |

mixing system(V:4500L) |

1 |

|

|

| driving device 90KW |

1 |

|||

| mixing device |

1 |

|||

| high speed rotary scraper 5.5KW |

4 |

|||

| discharging gate |

1 |

|||

| mixing tank |

1 |

|||

| sample device |

1 |

|||

|

13 |

storage hopper |

1 |

|

|

| hopper body |

1 |

|||

| vibrator MVE 60/3 |

2 |

|||

| impelled feeder |

1 |

|||

| rotary level meter |

1 |

|||

| pneumatic 4 phase valve |

1 |

|||

|

14 |

bulk and packing machine |

1 |

|

|

| bulk machine |

1 |

|||

| hopper body |

1 |

|||

| rotary level meter |

2 |

|||

| vibrator MVE 60/3 |

2 |

|||

| double exit packing machine |

1 |

|||

| belt machine (L=2500m,B=650mm,2.2kw) |

1 |

|||

|

|

||||

|

15 |

production hoist and delivery system |

1 |

|

|

| elevator(19m,15kw) |

1 |

|||

| ladder and platform |

1 |

|||

| chute of feeding and discharging gate |

1 |

|||

| rotary distributer |

1 |

|||

|

16 |

production bulk |

1 |

|

|

| chute of discharge |

4 |

|||

| pneumatic insert valve |

4 |

|||

| pneumatic valve(DN300) |

4 |

|||

| transition hopper |

1 |

|||

| bulk machine |

2 |

|||

|

17 |

Main building filter device |

1 |

|

|

| Pulse back flush filter 36m2 4KW |

1 |

|||

| filter pipes |

1 |

|||

| manual valve(DN150) |

2 |

|||

| pneumatic valve(DN250) |

1 |

|||

|

18 |

packing filter device |

1 |

|

|

| Pulse back flush filter 36m2 4KW |

1 |

|||

| manual valve(DN150) |

1 |

|||

| filter pipes |

1 |

|||

|

19 |

pneumatic system |

1 |

|

|

| air compressor |

1 |

|||

| storage tank 1m3 |

1 |

|||

| storage tank 0.3m3 |

2 |

|||

| main filter |

1 |

|||

| dryer |

1 |

|||

| joints |

1 |

|||

|

20 |

control system |

1 |

|

|

| industrial computer |

1 |

|||

| software |

1 |

|||

| electric components |

1 |

|||

| main frequency inverter |

1 |

|||

| LED monitor |

1 |

|||

| printer |

1 |

|||

| Power supply |

1 |

|||

| operation table |

1 |

|||

| electrical carbinet |

1 |

|||

| wires and cables |

1 |

|||

|

21 |

surveillance system |

1 |

|

|

| color camera |

4 |

|||

| amera lens |

4 |

|||

| 19 LED monitor |

1 |

|||

| insert DV |

1 |

|||

|

22 |

control room |

1 |

|

|

| control room frame |

1 |

|||

| inner and outer decoration |

1 |

|||

| illumation and switch |

1 |

|||

| air conditioner |

1 |

|||

|

23 |

Main steel structure |

1 |

|

|

| chassis |

1 |

|||

| ladder |

1 |

|||

| support leg |

1 |

|||

| Storage delivery equipment | ||||

|

|

|

|||

|

24 |

cement screw conveyor | φ219-2140 |

4 |

|

|

25 |

机additive screw conveyor | Ø114-2000 |

2 |

|

|

26 |

机additive screw conveyor | Ø114-1300 |

2 |

|

|

27 |

production screw conveyor(before elevator) | GX400-6500 |

1 |

|

|

28 |

production screw conveyor(after bulk machine and elevator) | GX400-5000 |

2 |

|

|

29 |

raw material storage bin (现场制作) |

1 |

|

|

| sand silo:dia 3.4m,V 90m3 |

4 |

|||

| 粉仓cement silo:dia 3.4m,V 90m3 |

4 |

|||

| manual valve |

4 |

|||

| level meter |

8 |

|||

| arch breaker |

4 |

|||

| manual valve |

4 |

|||

| level meter |

8 |

|||

| safe valve |

4 |

|||

| pulse back flush filter |

4 |

|||

| steel structure support |

1 |

|||

|

30 |

production storage silo |

|

||

| silo:dia 3.4m,V:75m3 |

4 |

|||

| arch breaker |

4 |

|||

| manual valve(DN300) |

4 |

|||

| rotary level meter |

8 |

|||

| (1.5kw)pulse back flush filter |

1 |

|||

| steel structure support |

1 |

|||

|

31 |

decoration |

1 |

|

|

| decoration 2500m2,(0.5mm) |

1 |

|||

| body frame, windows and doors |

1 |

|||

Product detail pictures:

Related Product Guide:

abide by the contract", conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for Good Quality China Supplier Concret Batching Plant Dry Italy - SjGJD060-3GStepped Type Dry Mortar batching plant – Janeoo , The product will supply to all over the world, such as: Colombia, Georgia, Guyana, Our mission is "Provide Products with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!