factory Outlets for Central Mix Concrete Batching Plant - S series SjHZN120S – Janeoo

factory Outlets for Central Mix Concrete Batching Plant - S series SjHZN120S – Janeoo Detail:

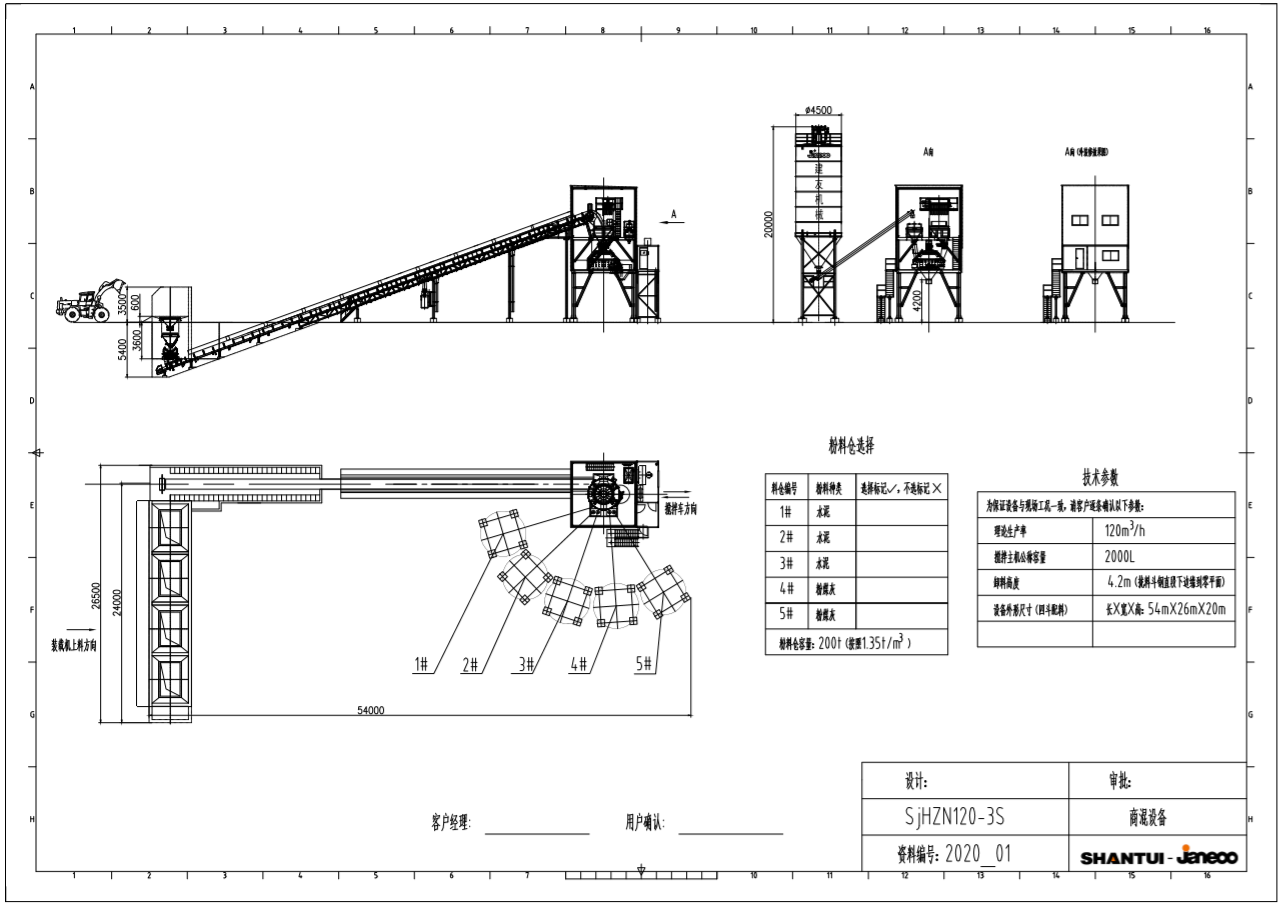

SjHZS120M configuration

1. Characteristics:

1.1. Heavy-duty frame structure with high overall stability;

1.2. Large internal space for easy maintenance;

1.3. negative pressure pulse back blowing dust removal,

sewage reuse, excellent environmental performance;

Applications : It is adapted to ready-mix concrete production.

2. Advantages

2.1 Stable main structure

1. The appearance is harmonious and beautiful, and with large internal maintenance space.

2. Large steel frame main structure, reasonable layout, stable structure.

2.2 Reliable aggregate batching system

2.3 High Efficient mixer

2.4 High precision metering system

2.5 Easy to maintain belt conveyor system

2.6 Air control system with reasonable layout

2.7 High accuracy application technology

SjHZS120M configuration

|

No. |

Description |

Item |

Qty |

Remark |

|

1 |

Aggregates batching system (4 hoppers ground type) |

Storage hopper |

4 |

2 vibrator for 2 sand hoppers |

| Weighing hopper(2000kg±2%) |

4 |

|||

| cylinder |

3×4 |

|||

| Sensor |

3×4 |

|||

| Belt machine(B:1000mm,P:5.5KW) |

1 |

|||

|

2 |

Inclined belt machine |

Main support |

1 |

|

| Driving device(功率:37kW) |

1 |

|||

| Belt(B:1000mm) |

1 |

|||

| Water washing device |

1 |

|||

|

3 |

Main building |

Main structure(2 layers platform) |

1 |

|

| Discharging hopper |

1 |

|||

| Bag type filter |

1 |

|||

| Decoration |

1 |

|||

|

4 |

vertical planetary mixer |

V:2.0 m3(P:90kW) |

1 |

|

| Hydraulic structure |

1 |

|||

| Centralized lubrication system |

1 |

|||

|

5 |

Middle hopper |

Storage hopper |

1 |

|

| vibrator |

1 |

|||

| cylinder |

2 |

|||

|

6 |

Cement weighing system |

Weighing hopper(1000kg±1%) |

1 |

|

| sensor |

3 |

|||

| Discharging valve(DN300) |

1 |

|||

| vibrator |

1 |

|||

|

7 |

Powder weighing system

|

Weighing hopper(400kg±1%) |

1 |

|

| sensor |

3 |

|||

| Discharging valve(DN300) |

1 |

|||

| vibrator |

1 |

|||

|

8 |

Water weighing system |

Weighing hopper(500kg±1%) |

1 |

|

| sensor |

1 |

|||

| discharging valve (DN150) |

1 |

|||

| Water pump |

1 |

|||

| Weighing valve(DN80) |

1 |

|||

| Weighing pipes |

1 |

|||

|

9 |

Additive weighing system |

Weighing hopper(50kg±1%) |

1 |

PE additive tank |

| sensor |

1 |

|||

| Discharging valve |

1 |

|||

| Storage tank(V:10m3) |

2 |

|||

| Additive pump |

2 |

|||

| Weighing pipes |

2 |

|||

|

10 |

Pneumatic system |

Air compressor(displacement:1.6 m3/min) |

1 |

|

| Sotrage tank 1m3+0.3m3 |

1套 |

|||

| Filter and valve |

1 |

|||

|

11 |

Control room |

decoration |

1 |

|

| Air conditioner |

1 |

|||

|

12 |

Electrical system |

software |

1 |

|

| Industrial computer and monitor |

1 |

|||

| UPS power |

1 |

|||

| Printer |

1 |

|||

| Operation table |

1 |

|||

| Electrical carbin and |

1 |

|||

| Monitoring system(1 monitor+4 cameras) |

1 |

|||

| Optional | ||||

|

No. |

Description |

Item |

QTY |

Remark |

|

13 |

Cement silo |

200t |

5 |

Cement density 1.35t/m3 |

| Maintenance platform |

1 |

|

||

|

14 |

Accessoies |

24㎡ filter |

5 |

|

| Safe valve on the top |

5 |

|||

| Level meter |

2X5 |

|||

| Arch breaker |

5 |

|||

| Manual valve |

5 |

|||

|

15 |

Screw conveyor |

φ273X11m |

3 |

cement |

| φ219X11m |

2 |

powder |

||

Product detail pictures:

Related Product Guide:

Our primary purpose is to give our shoppers a serious and responsible company relationship, giving personalized attention to all of them for factory Outlets for Central Mix Concrete Batching Plant - S series SjHZN120S – Janeoo , The product will supply to all over the world, such as: Slovenia, Albania, Oslo, "Make the women more attractive "is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We are strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!