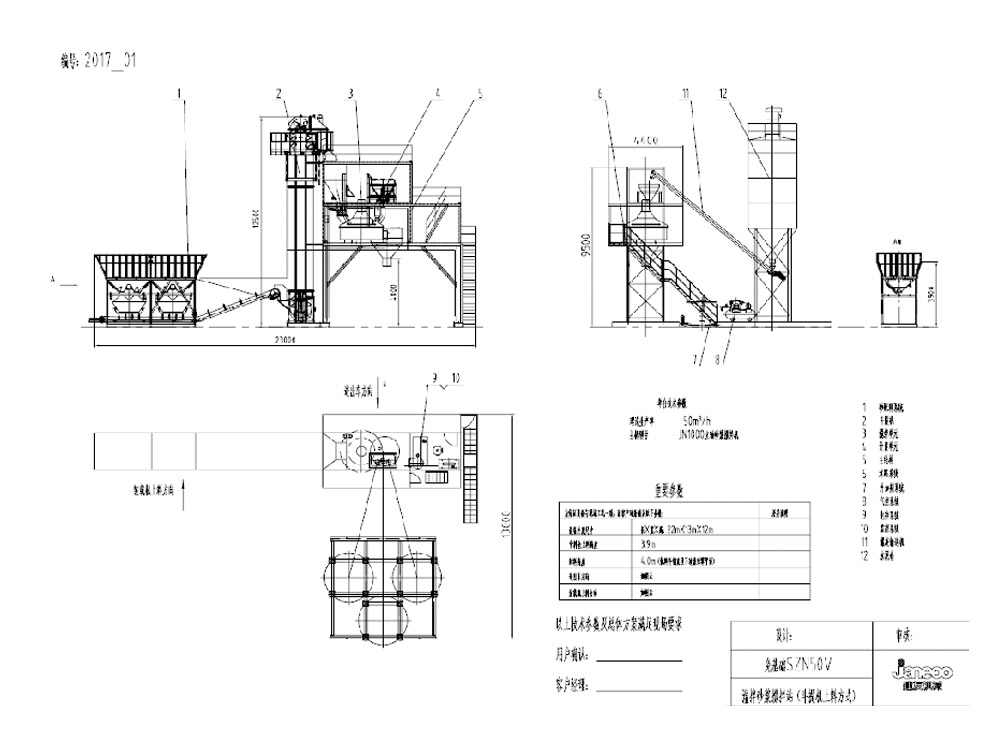

Factory For 50m3/H Hzs50 Small Concrete Batching Plant - Water platform concrete batching plant – Janeoo

Factory For 50m3/H Hzs50 Small Concrete Batching Plant - Water platform concrete batching plant – Janeoo Detail:

Features

1.It’s suitable for production of water construction, and the special structure meets the requirements of the water enviroment.

2.Compact structure can reduce the construction cost of the platform.

3.The equipment has high safety and can adapt to the platform foundation settlement and the influence of typhoon.

4.Equipped with large volume aggregate bins, one-time feeding can meet the production of 500m3 of concrete(can be customized according to requirements), equipped with movable cover to meet the normal construction in rain and snow.

Specification

| Mode | HZS60ME | HZS90ME | HZS120ME | HZS180ME | |

| Theoretical productivity m³/h | 60 | 90 | 120 | 180 | |

| Mixer | Mode | JS1000 | JS1500 | JS2000 | JS3000 |

| Driving power(Kw) | 2X 18.5 | 2X 30 | 2X37 | 2X55 | |

| Discharging capacity(L) | 1000 | 1500 | 2000 | 3000 | |

| Max. aggregate size(Gravel/Pebblemm) | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | |

| Batching bin | Stone bin volume m³ | 2X150 | 2X150 | 2X300 | 2X300 |

| Sand bin volume m³ | 200 | 200 | 400 | 400 | |

| Powder silo m³ | 100 | 100 | 200 | 200 | |

| Belt conveyor capacity t/h | 200 | 300 | 400 | 600 | |

| Weighing range and measurement accuracy | Aggregate kg | 3X(1000±2%) | 3X(1500±2%) | 3X(2000±2%) | 3X(3000±2%) |

| Cement kg | 500±1% | 800±1% | 1000±1% | 1500±1% | |

| Flyash kg | 150±1% | 200±1% | 400±1% | 600±1% | |

| Water kg | 200±1% | 300±1% | 400±1% | 600±1% | |

| Additive kg | 20±1% | 30±1% | 40±1% | 60±1% | |

| Discharging height m | 4.2 | 4.2 | 4.2 | 4.2 | |

| Total power kW | 100 | 150 | 200 | 250 | |

Product detail pictures:

Related Product Guide:

Our commission is always to provide our customers and clientele with best quality and aggressive portable digital products for Factory For 50m3/H Hzs50 Small Concrete Batching Plant - Water platform concrete batching plant – Janeoo , The product will supply to all over the world, such as: Azerbaijan, Uganda, Poland, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!

Write your message here and send it to us