Concrete Truck Mixer 8×4

Introduction of truck mixer (+Qualification introduction)

Shantui Janeoo has been developing and producing concrete truck mixer since the 1980s. It has accumulated rich experience in design, manufacturing and after-sales service. Concrete truck mixer has won many provincial and municipal scientific and technological progress awards. From domestic large-scale commercial mixing plant customers to national key engineering projects, exported to Mongolia, Southeast Asia, Africa, Eastern Europe and many other countries.

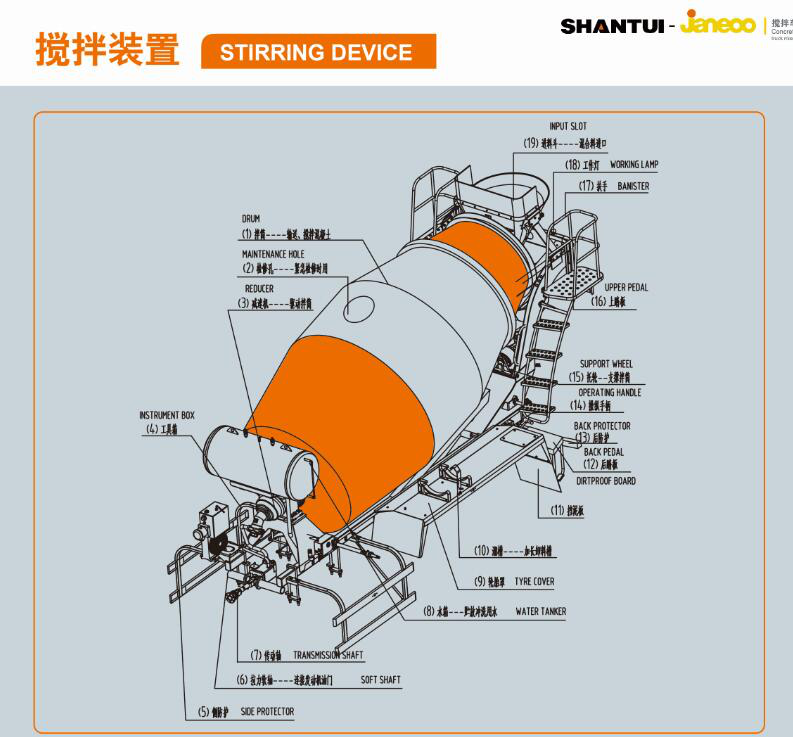

Stirring device

Stirring device

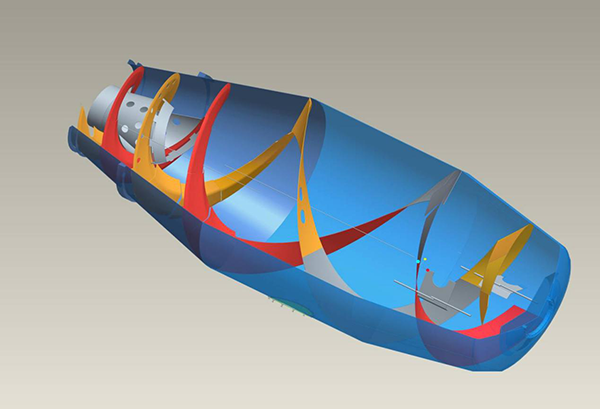

1.Mixer drum and blade

Mixer drun

Large volume, loaded with concrete of rated volume, under normal working conditions (slope ≤14%), there will be no overflow, leakage, etc.;

The mixer drum adopts high-strength wear-resistant steel plate B520JJ, so that the life can reach 8~10 years;

Welding of mixer drum adopt automatic robot welding, making the quality more reliable.

The residual rate of discharge is less than 0.5% (1% of the national standard), the homogeneity of the concrete is good, the feed and discharge speed is high, the feed speed is> 5m³/min, and the discharge speed is > 2.6m³/min.

The blade is made of high-strength wear-resistant steel plate, equipped with better variable pitch refined logarithmic helix and concave hyperbolic shape stirring blade

The blades are reasonably arranged with square and round holes, which are manufactured by computer-aided design and pressed by a variety of special molds to achieve three-dimensional stirring. At the same time, the stirring is more rapid and uniform, and the phenomenon of segregation is completely eliminated, so that the transportation distance can be appropriately extended and expanded. Therefore, the transportation distance can be extended properly, and the operation scope of the concrete company is expanded.

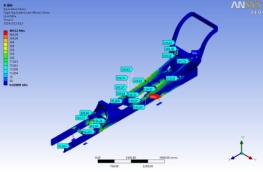

2.Frame

Perform finite element analysis and equipped with flexible connections to reduce impact

Split front desk to eliminate stress concentration and enhance overall rigidity

The frame material is made of 16Mn steel with high strength

3.chassis

Sinotruk second-class chassis is refitted with good power, low fuel consumption and reliability in use.

Power: MAN power, good vehicle stability, high attendance, fuel consumption and other advantages

Low fuel consumption: The new combustion principle improves the efficiency of the engine and reduces fuel consumption. Using Bosch's second-generation common rail fuel injection system (ECD17), the performance is even better. 1200-1800 rpm ultra-wide economic speed and low fuel consumption area. Case example: The fuel consumption of the five-platform mixer truck in Chongqing region is between 35-55L/100km. If the standard loading transportation, heavy load transportation, fuel consumption is 3-5L less than the industry.

High reliability: The integral cylinder head is made of special cast iron and fastened with bolts. Ceramic honing is performed on the working surface of the cylinder hole of the machine body, so as to achieve the best wear ability and fuel consumption. The overall strength, reliability and sealing are better. B10 life span reaches 800,000 kilometers, the most advanced level of international medium and heavy truck engines

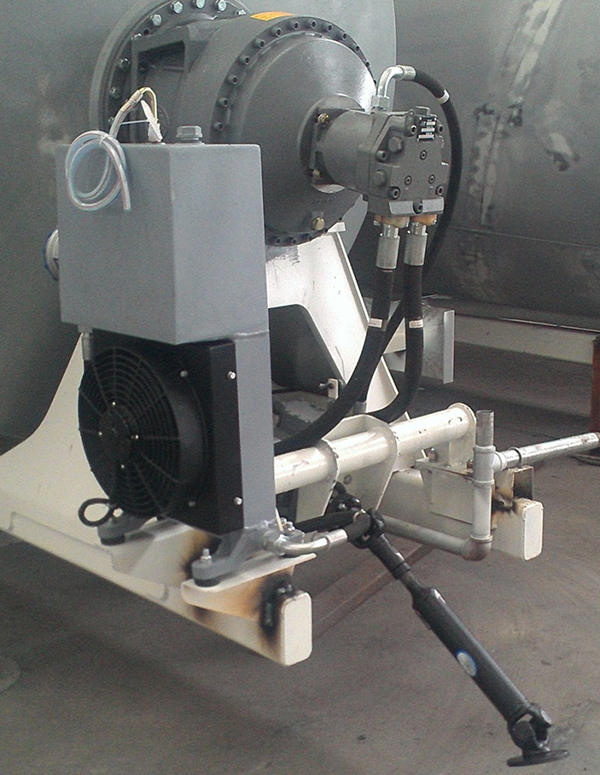

4.Hydraulic system

1. The hydraulic pump, hydraulic motor, and reducer equipped with International famous brands with safe and reliable performance.

2.Strictly control the purchase link, there will be no simple matching and low matching, ensure genuine products, and Let customers use it with confidence.

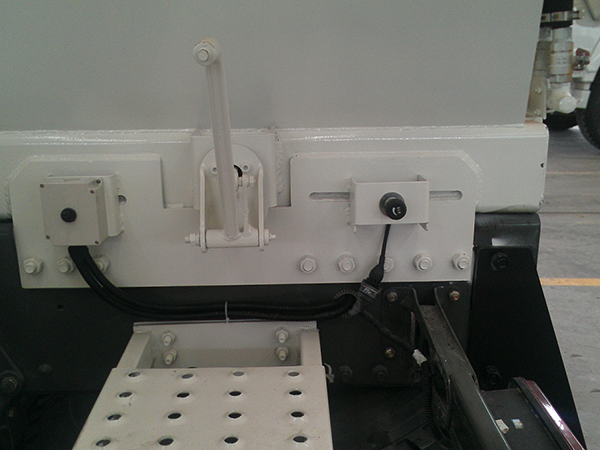

5.Operation method

1.The operation is controlled by a flexible shaft type and a mechanical operation type, which mainly control the forward and reverse rotation of the mixer drum , the rotating speed of the mixer drum.

2.Flexible shaft operation: composed of an operating handle and a flexible shaft, which can control the rotation direction of the mixer drum, adjust the engine throttle and have a locking function, the handle is small and beautiful, and the operation is more relaxed, flexible and reliable.

3.Mechanical operation: durable, can be controlled in the cab and operated on the left and right sides of the vehicle.

6.Water washing system

1. Adopt air pressure water supply method, with large-capacity water tank, quick water addition and exhaust.

2. Equipped with various valves and instruments, the sealing performance is best, which can ensure the driving and cleaning needs.

3.The pipeline can reach the mixer drum and the feed tank separately, and is equipped with a high-pressure water gun, which can clean the vehicle in all directions, which is convenient and fast.

7.Blind area image assembly (optional)

The system can realize automatic alarm in the dangerous area near the two sides of the vehicle. At the same time, it can observe the situation behind the side through the in-vehicle video when turning, effectively eliminating the driver's visual blind spot and ensuring driving safety.

Technical parameters (domestic)

|

Name |

SDX5310GJBF1 |

SDX5313GJBE1 |

SDX5318GJBE1 |

| Performance parameter | |||

| Empty weight(kg) |

14500 |

14130 |

18890 |

| Rated carrying capacity(kg) |

16370 |

16740 |

|

| Mixing capacity(m³) |

7.49 |

7.32 |

5.2 |

| Mixer drum performance | |||

| Input speed(m³/min) |

5.2 |

5.2 |

5 |

| Discharge speed(m³/min) |

2.6 |

2.6 |

2.6 |

| Discharge residual rate |

<0.6% |

<0.6% |

<0.6% |

| Slump mm |

40-210 |

40-210 |

40-210 |

| Dimensions | |||

| Length(mm) |

9900 |

10060 |

11960 |

| Width(mm) |

2500 |

2500 |

2500 |

| Height(mm) |

3950 |

3950 |

4000 |

| Hydraulic system | |||

| hydraulic pump, hydraulic motor,reducer |

International famous brand |

International famous brand |

International famous brand |

| Water supply type | |||

| Water supply mode |

Pneumatic water supply |

Pneumatic water supply |

Pneumatic water supply |

| Water tanker |

500L, can be customized |

500L, can be customized |

500L, can be customized |

| Vehicle chassis | |||

| Driving type |

8X4 |

8X4 |

8X4 |

| Brand |

sinotruk |

sinotruk |

sinotruk |

| Maximum speed (km/h) |

82 |

82 |

80 |

| engine model |

MC07.34-60/WP8.350E61 |

MC07.34-50 |

D10.38-50 |

| Fuel type |

Diesel |

Diesel |

Diesel |

| Emission Standards |

国六 |

国五 |

国五 |

| Number of tires |

12 |

12 |

12 |

| Tire specifications |

11.00R20 18PR |

11.00R20 18PR |

12.00R20 18PR |

Technical Parameters

Mixer drum performance,Input speed,Discharge speed,Discharge residual rate,Slump

Water supply type,Water supply mode,Water tank capacity,Pneumatic water supply

Hydraulic system hydraulic pump, hydraulic motor,reducer,International famous brand

Vehicle chassis,Driving type,Brand,sinotruk,shacman

|

Mixer truck tank parameters |

|||

| Tank material | Alloy steel (special wear-resistant material --- more than 3 times the life of the tank) | Body material | 16Mn 6mm Alloy steel |

| Blade material: | 5mm Alloy steel(Adding wear-resistant strips to improve service life) | Head material | 8mm Double head alloy steel |

| Reducer | Keyi ,jungong | Hydraulic valve | 15 Single |

| water supply system | 200L water tank,Pneumatic water supply system | cooling system | 18(L) |

| Feeding speed: | ( m3/min≥3)Input speed | Output speed: | m3/min ≥ 2Discharge speed |

| dischargeresidual rate | (%)≤0.5Discharge residual rate | Operation method | left and right |

| Discharge range | 180°Up, down, left and right, height adjustment | safety devices | Installation of leaky material receiving device |

| 2 m³mixer truck chassis parameters | |||

| Vehicle name: | 2 m³ mixer truck | Axle | Dongfeng Special axle |

| engine | weichai4100 | Steering Type | Steering wheel hydraulic boost |

| Dimensions | 5800*2000*2600 | Service brake | Pneumatic brake |

| total weight | 2500(Kg) | Parking brake | Pneumatic brake |

Special model Tunnel dedicated

| Empty weight | 1020(kg) | Number of spring leaves | 1315Front 13 rear 15 |

| Engine power | 62KW | Wheelbase | 2500 |

| Number of axes | 2(4*2) | max speed | 60(km/h) |

| transmission | 145 transmission,Direction assist | Rear axle | 1064 |

| Number of tires | 6 | Tire | 750-16 |

|

3 m³mixer truck chassis parameters |

|||

| Vehicle name: | Dimensions | 5800*2000*2600 | |

| engine | 4102 | Displacement | 1596 |

| total weight | 2500(Kg) | Number of spring leaves | Front 13 rear 15 |

| Empty weight | 1020(kg) | Rated weight | 1030(kg) |

| Engine power | 76KW | Wheelbase | 2700 |

| Number of axes | 2(4*2) | max speed | 60(km/h) |

| transmission | 145 transmission,Direction assist | Front and rear axles | 1064 |

| Number of tires | 6 | Tire specifications | 825-16 |

|

Mixer truck tank parameters |

|||

| Tank material | Alloy steel (special wear-resistant material --- more than 3 times the life of the tank) | Body material | 16Mn 6mm Alloy steel |

| Blade material: | Alloy steel(Adding wear-resistant strips to improve service life) | Head material | 8# Double head alloy steel |

| Reducer | Planetary reducer with large reduction ratio | Hydraulic valve | 15 Single |

| water supply system | 200L water tank,Pneumatic water supply system | cooling system | 18LTemperature controlled radiator |

| Feeding speed: | (m3/min≥3)Input speed | Output speed: | m3/min ≥ 2Discharge speed |

| dischargeresidual rate | (%)≤0.5Discharge residual rate | Operation method | Trilateral operation of left and right sides and cab |

| Discharge range | 180°Up, down, left and right, height adjustment | safety devices | Installation of leaky material receiving device |

| 4 m³>mixer truck chassis parameters | |||

| Vehicle name: | 4 m³mixer truck | Dimensions | 6400*2000*2800 |

| engine | 4105 | (mlDisplacement | 1596 |

|

total weight |

2500(Kg) | Number of spring leaves | Front 13 rear 15 |

| Wheelbase | 2700 | max speed | 60(km/h) |

|

transmission |

145 transmission,Direction assist | rear axles | 1088 |

| Number of tires | 6 |

Tire specifications |

825-16 |

| Service brake | Pneumatic brake | Steering Type | Steering wheel, hydraulic power |

| Mixer truck tank parameters | |||

| Tank material | Alloy steel (special wear-resistant material --- more than 3 times the life of the tank) | Body material | 16Mn 6mm Alloy steel |

| Blade material: | 5#Alloy steel(Adding wear-resistant strips to improve service life) | Head material | 8# Double head alloy steel |

| Reducer | Planetary reducer with large reduction ratio | Hydraulic valve | 15 Single |

| water supply system | 200L water tank,Pneumatic water supply system | cooling system | 18LTemperature controlled radiator |

| Feeding speed: | (m3/min≥3)Input speed | Output speed: | m3/min ≥ 2Discharge speed |

| dischargeresidual rate | (%)≤0.5Discharge residual rate | Operation method | Trilateral operation of left and right sides and cab |

| Discharge range | 180°Up, down, left and right, height adjustment | safety devices | Installation of leaky material receiving device |

Self-loading concrete truck mixer